Plywood, versatile and ubiquitous, finds its way into many home and professional projects. The ability to achieve a clean and precise cut can elevate the end result from mediocre to impeccable. Yet, one common challenge faced by many is the dreaded splintering effect.

Cutting plywood with a hand saw without resulting in splinters is a combination of technique, preparation, and tool selection. When done right, the cut is clean, enhancing the beauty and structural integrity of the project.

Splinters aren’t just unsightly; they compromise the quality of your work. Achieving splinter-free cuts signifies attention to detail and ensures the longevity of the completed project.

Plywood Basics

Types and Characteristics

Plywood, a layered material, is made up of veneers bonded together with adhesive. Each layer’s grain direction is perpendicular to the adjacent one, providing strength and reducing shrinkage.

Common Uses and Applications

From furniture to flooring, plywood’s diverse applications stem from its durability and adaptability. Its strength-to-weight ratio makes it ideal for large installations like cabinetry and wall paneling.

Importance of a Clean Cut

A seamless cut not only looks professional but also ensures structural integrity. Ragged edges can cause layer separation, leading to decreased plywood lifespan.

Selecting the Right Hand Saw

When it comes to woodworking, especially with materials as delicate as plywood, the type of hand saw used can significantly affect the end result. Choosing the right saw isn’t just about brand preference or cost, but understanding the nuances of each type, its specific application, and how it interacts with plywood.

Types of Hand Saws

- Back Saws: These are recognizable by their stiff rib or spine on the back, which gives them their name. Back saws are particularly suitable for making precise miter cuts, usually in conjunction with a miter box to ensure accuracy.

- Advantages:

- Provides straight cuts due to its rigidity.

- Offers more control due to its short length.

- Great for joinery tasks such as dovetails.

- Limitations:

- Not suitable for long ripping tasks.

- Might not be the best choice for thicker plywood sheets.

- Advantages:

- Pull Saws: Originating from Japan, pull saws are unique in that they cut on the pull stroke, unlike most Western saws that cut on the push. They tend to have a thinner blade, which reduces friction and results in a smoother cut.

- Advantages:

- Provides extremely clean cuts.

- The thin blade means less material wastage.

- Ideal for intricate, detailed work.

- Limitations:

- Might require some practice for those used to Western saws.

- Blades are delicate and can bend if not handled correctly.

- Advantages:

- Crosscut Saws: These saws are specifically designed for cutting wood perpendicular to the grain. Their teeth are shaped to cut and remove wood fibers, ensuring a clean finish.

- Advantages:

- Best for cutting across the grain of plywood.

- Typically more aggressive, ensuring faster cuts.

- Limitations:

- Not ideal for ripping or long cuts along the grain.

- Advantages:

Teeth Configuration and Size

A saw’s efficiency is heavily influenced by its teeth configuration. The number of teeth per inch (TPI) and their shape play pivotal roles in determining the type of cut – rough or smooth.

- Higher TPI (10-12): Ideal for plywood due to the smoother finish. The closely spaced teeth make for slower, but neater cuts.

- Lower TPI (below 10): More aggressive and faster, but can result in a rougher finish. Suitable for thicker materials but may lead to more splinters with plywood.

Material and Design Considerations

While most saws boast steel blades, the quality can vary. Hardened or tempered steel blades retain their sharpness longer, ensuring consistent results. The handle’s ergonomic design can significantly impact your comfort and cutting accuracy. Look for:

- Handles: Opt for ones with a good grip and ergonomic design. A comfortable handle allows for prolonged work without discomfort.

- Blade Material: High carbon steel is preferred due to its sharpness and durability. Some blades may come with a protective coating to prevent rusting and reduce friction.

- Adjustability: Some modern hand saws offer adjustable blade angles or tension, allowing for more versatility in cutting.

Plywood Splinters: The Challenge

Even seasoned woodworkers sometimes face the splintering issue, an undesirable effect where the top veneer layer gets chipped or ripped off during the cut. Splintering isn’t just an aesthetic problem; it can compromise the structural integrity of a project.

- Causes of Splintering:

- Rapid cutting without considering the plywood grain.

- Using a dull or inappropriate saw.

- Inadequate support during the cutting process.

- Effects of Splintering:

- Aesthetic Implications: Splintered edges look unprofessional and unfinished.

- Structural Concerns: Splintering can weaken joints and overall construction, especially in projects where precision is paramount.

Preparation for Cutting

Like all tasks requiring precision, preparation is key. The steps taken before the actual cut can drastically affect the final result.

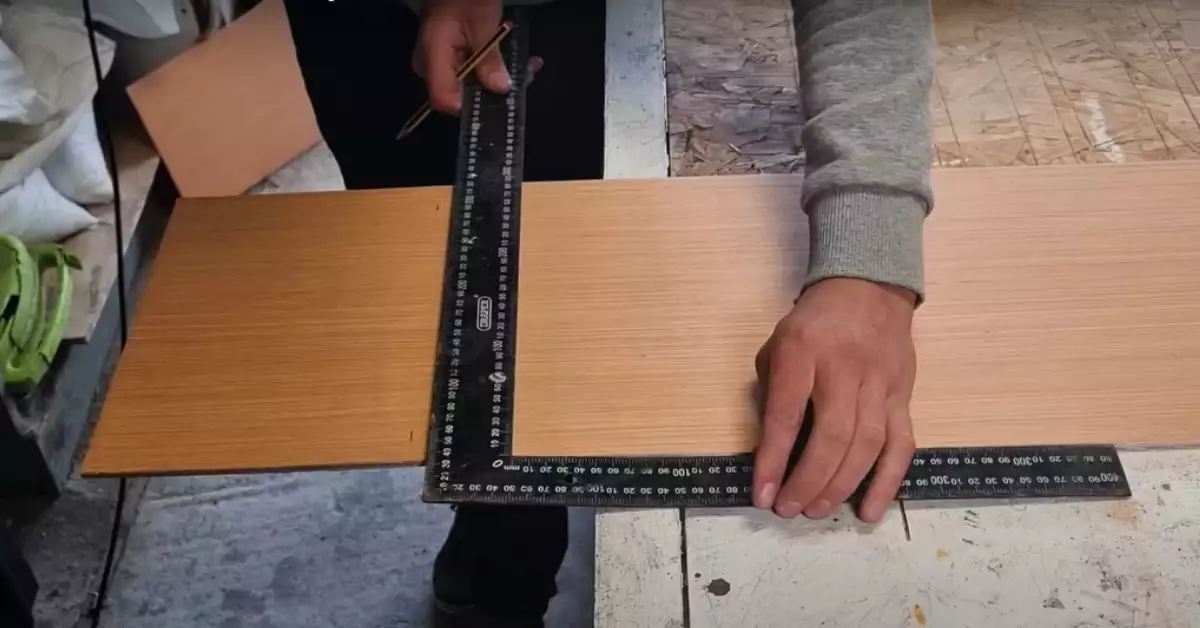

Marking the Cutting Line

Being precise from the start ensures a higher chance of achieving a clean cut. Use a good-quality straightedge and a visible pencil or marker. A clear line not only guides the saw but also provides a visual checkpoint to ensure alignment.

Choosing the Right Workspace

- Stable Surface: This is non-negotiable. An unstable surface can lead to inaccuracies and increase the risk of splintering or even injury.

- Elevation: Using sawhorses or a workbench can elevate the plywood, ensuring you’re working at a comfortable height and can easily see and follow your marked line.

Clamping and Securing the Plywood

Movement during cutting is a prime cause of inaccuracies. Use clamps to securely hold the plywood in place, ensuring:

- No Slippage: The clamps should be tight enough to prevent any movement of the plywood.

- No Damage: Ensure clamps don’t damage or dent the wood surface. Using soft jaw covers or placing a soft material between the clamp and plywood can help.

Cutting Techniques

The actual cutting process requires a combination of skill, technique, and understanding of the tool in hand.

Proper Hand Saw Positioning

- Angle of Attack: Holding the saw at around a 60° angle to the plywood surface has been found optimal. It’s a balance between speed and control, ensuring the blade interacts correctly with the wood grain.

Direction and Force Considerations

- Push vs. Pull: Remember, force application varies based on the saw type. Using the correct force direction minimizes splinter risks and ensures a cleaner cut.

- Consistent Force: Whether you’re using a push or pull method, ensure the force remains consistent throughout the cut. This uniformity prevents jagged or uneven edges.

Key Tips for a Clean Cut

- Stay on the Line: Regularly check alignment with the marked line.

- Controlled Speed: Rushing might cause jagged edges. A steady pace ensures uniformity.

- Maintain Saw Sharpness: Regularly sharpen the saw to maintain its cutting efficiency.

Minimizing Splintering

Tape Method

Place masking tape along the cutting line. This keeps the veneer in place, reducing the chances of splinters.

Correct Blade Pull or Push Direction

Remember, the force direction varies based on the saw type. Stick to the right direction to minimize splinter risks.

Keeping the Saw Sharp

A dull blade increases the chances of splintering. Sharpen regularly or consider a replacement for optimal performance.

Safety Precautions

Protective Gear

Always wear safety goggles and gloves. They shield from splinters and sawdust, ensuring a safer working environment.

Hand Positioning and Movement

Keep hands away from the saw’s path. A firm yet relaxed grip provides better control.

Disposal of Waste

Post-cutting, collect and dispose of all splinters and sawdust. This prevents potential hazards and keeps the workspace tidy.

Maintenance and Care

Sharpening the Hand Saw

Tools perform best when well-maintained. Use a file or a sharpening service to keep the saw’s teeth in top condition.

Storing Tools

Store the hand saw in a dry location, away from humidity. This prevents rusting and keeps the tool ready for the next task.

Cleaning

After each use, wipe down the saw blade with a cloth to remove any residual wood particles or adhesive.

Frequently Asked Questions

How often should I sharpen my hand saw?

It depends on usage frequency, but a general rule is to sharpen when you notice reduced cutting efficiency or increased splintering.

Can I use any tape for the tape method?

While any tape can offer some benefit, masking tape or painter’s tape is ideal due to its easy removability without leaving residue.

Does plywood thickness affect the cutting technique?

Yes, thicker plywood may require slower cutting speeds and saws with fewer teeth for optimal results.

Conclusion

Achieving the perfect cut in plywood, devoid of splinters, is an art backed by science. The synergy between the right tools and technique transforms any plywood project, elevating its aesthetics and functionality.

Splinter-free plywood not only looks appealing but also assures the safety and durability of the project. The nuances of selecting the appropriate hand saw, understanding plywood dynamics, and mastering cutting techniques underscore this craft’s precision.

In the world of woodworking, the difference between mediocrity and mastery often hinges on the details. Perfecting the plywood cut epitomizes this sentiment, making every project a testament to skill and dedication.

Leave a Reply